The deburring equipment is indispensable equipment in manufacturing and processing industrial, its main functions are: remove burrs, flash, and uneven edges in workpiece surfaces, thus to enhance product quality and aesthetics. If you operate the machine correctly, it will improve its efficiency and also extends equipment life span and ensure your safety. Now you got a metal deburring machine, here’s a detailed guide for your reference:

I. Equipment Selection and Preparation:

1. Select Suitable machine model and type

There are many kinds of deburring machines available, including manual deburring, mechanical deburring machines and also chemical deburring systems, etc. You have to compare and make decision upon your workpiece material, shape, and processing requirements. Here are the examples:

- Metal workpieces: Opt for mechanical deburring machines.

- Plastic or soft materials: Manual tools may be more appropriate.

2. Make sure Machine working condition

Before power on the machine, please always ensure all functions (power supply, cutting tools, transmission systems, etc.) are workable.

3. Prepare Workpieces

All the workpieces have to be compatible with the machine available in all aspects.

II. Operating Steps:

1.Prepare Protective Gears

Operators MUST wear safety goggles, gloves, and earplugs to shield against flying debris and noise.

2. Adjust Equipment Parameters

Set up correct parameters (e.g., speed, feed rate, and pressure) according to material and processing needs.

3.Put the Workpieces stably

Firmly fix workpieces on the worktable to prevent movement during operation. Heavy/large items may require additional fixtures.

4.Proceed Deburring

Apply proper technique and always monitor operation, adjust parameters, or replace tools as needed.

5.Quality Inspection

After-deburring, check the surfaces to confirm complete burr/flash removal and smoothness. Re-process defective workpieces.

III. Maintenance and Care:

1.Regular Cleaning

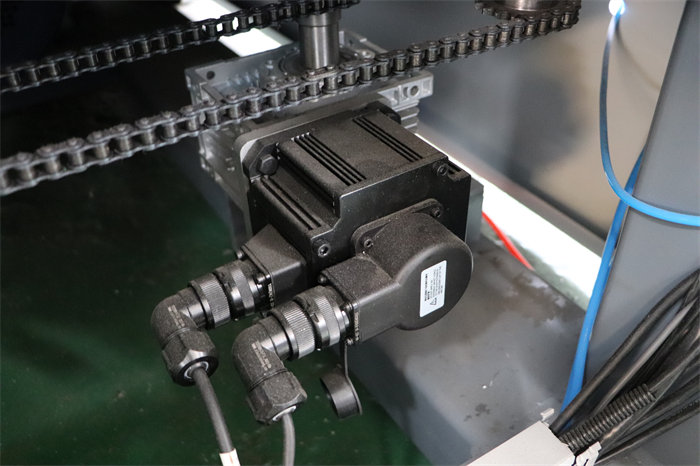

Remove debris and oil after use. Perform deep cleaning periodically, especially transmission systems

2. Check deburring wheels

Inspect grinding wheels regularly and replace severely worn ones promptly. Worn tools compromise quality and may cause equipment failure.

3. Lubrication and Servicing

Lubricate moving parts as per the manual. Suggest to inspect transmission and electrical systems routinely.

4. Machine loading

The machine should be kept in dry, ventilated areas away from moisture and dust.

IV. Safety Precautions

1.Follow Operating manual

Strictly adhere to guidelines; operators MUST receive professional instruction.

2.Avoid Overloading

Stop prolonged overloading and focus on the equipment status .

3. Electrical Safety

Ensure power cords are intact to prevent leaks/short circuits. Inspect electrical systems periodically.

4. Emergency Response

In case of malfunctions or accidents:

- Immediately stop operations.

- Implement emergency measures.

- Report severe incidents to our experts.

V. Conclusion

Proper deburring requires operator expertise, strict compliance with procedures, and safety protocols. By appropriate selection, preparation, operation, and maintenance, your machine can maximize performance, enhance efficiency, and prolong service life. Adjust and optimize practices based on specific scenarios for optimal results. If you have any interest, welcome to contact us via email tiptop@tiptopmfg.com for a formal quote and talk to LETIPTOP expert to get the support. For more information, please click deburring machine to view.